If you’re in the business of making or repairing shoes, having a reliable and efficient sewing machine is crucial to your success. And when it comes to shoemaking, nothing beats the precision and durability of a cobbler sewing machine.

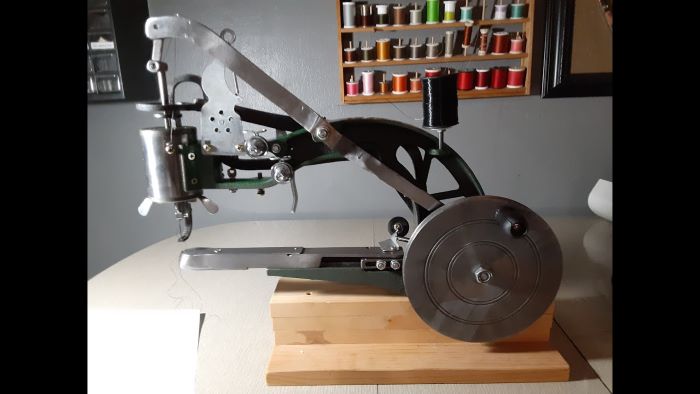

Cobbler sewing machines are specialized machines that are designed to handle heavy-duty materials such as leather, rubber, and canvas. They feature powerful motors, sturdy construction, and a range of specialized accessories that make them ideal for shoemaking and other leathercraft projects.

In this guide, we’ll take a closer look at what makes these machines unique, how they work, and why you should consider investing in one for your business.

A cobbler sewing machine is a specialized type of sewing machine that is designed for shoemaking and other heavy-duty leathercraft projects. These machines are typically larger and more powerful than standard sewing machines, and they feature a range of specialized accessories and features that make them ideal for working with leather and other tough materials.

Cobbler using a sewing machine

These can be used for a variety of shoemaking tasks, including stitching together leather uppers, sewing soles onto shoes, and repairing worn-out shoes.

Cobbler sewing machines work in much the same way as standard sewing machines, but with a few key differences. Most of them are designed to sew with a lockstitch, which is a strong, durable stitch that is commonly used in shoemaking and other heavy-duty sewing projects.

To create a lockstitch, two threads are used a top thread and a bottom thread. That thread is interlocked in the fabric being sewn. The machine uses a specialized needle that is designed to puncture through rigid materials like leather and rubber. A heavy-duty motor that can handle the added resistance of these materials.

Cobbler sewing machines may also feature specialized accessories, such as roller feet, feed dogs, and edge guides, that help to ensure precise and consistent stitching.

There are several benefits to using a cobbler sewing machine for your shoemaking business or leathercraft projects, including:

- Durability: Cobbler sewing machines are designed to handle heavy-duty materials and can withstand the wear and tear of frequent use.

- Precision: With specialized accessories and features, these can help you achieve precise and consistent stitching, even when working with tough materials.

- Speed: They are designed to work quickly and efficiently, allowing you to complete projects faster and more efficiently than with a standard sewing machine.

- Versatility: While cobbler sewing machines are primarily designed for shoemaking, they can also be used for various other leathercraft projects, such as making bags, belts, and wallets.

When choosing a cobbler sewing machine, there are several factors to consider, including:

- Budget: Set a budget for your purchase and look for machines that fit within that budget. While higher-end machines may offer more features and durability, they can also be more expensive.

- Motor Power: Look for a machine with a powerful motor that can handle the tough materials you’ll be working with.

- Stitch Types: Make sure the machine can create the types of stitches you need for your shoemaking projects.

- Throat Size: The throat size of the machine will determine how large of a piece of material you can sew at one time.

- Brand and Quality: Consider purchasing from reputable brands and manufacturers to ensure the machine is of high quality and will last for a long time.

Must read: Best Sewing Machine for Advanced Sewers

There are several types of cobbler sewing machines available on the market, each with its unique features and benefits. Some of the most common types include:

- Flat Bed Cobbler Sewing Machine: This is a basic cobbler sewing machine with a flat surface that makes it easier to sew straight lines. It is ideal for beginners and those who need a simple machine for occasional use.

- Post Bed Cobbler Sewing Machine: This type of machine has a vertical post behind the needle that allows the user to sew in tight spaces or around curved surfaces. It is commonly used for shoe repairs and leather work.

- Cylinder Bed Cobbler Sewing Machine: This machine has a cylindrical bed that allows the user to sew in a circular motion, making it ideal for sewing shoes and other round objects.

- Long Arm Cobbler Sewing Machine: This type of machine has an extended arm that allows the user to sew in hard-to-reach areas, such as the inside of a shoe or the bottom of a bag.

- Patching Machine: A patching machine is a specialized cobbler sewing machine used for repairing holes in shoes and leather goods. It is designed to sew patches onto damaged areas quickly and efficiently.

- Heavy-Duty Cobbler Sewing Machine: This machine is designed for heavy-duty use and can handle thicker materials like leather and canvas. It is ideal for professionals who need a reliable machine for daily use.

Keep your cobbler sewing machine in top condition and ensure its longevity, it’s important to perform regular maintenance and care. Here are a few tips to keep in mind:

Clean your machine regularly to remove dirt, dust, and debris that can accumulate in the crevices and moving parts.

Change needles regularly: Change the needles regularly, as dull or bent needles can damage the machine and fabric.

Check the tension: Check the thread tension regularly and adjust it as needed. Improper tension can cause stitches to be uneven or break.

Use high-quality thread: Use high-quality thread that is appropriate for the type of fabric you are sewing. Cheap or low-quality thread can cause thread breakage and damage to the machine.

Store it properly: When not in use, cover the machine with a dust cover or store it in a case. Store it in a cool, dry place away from direct sunlight.

Get it serviced regularly: Have the machine serviced by a professional regularly to keep it in top condition. They can identify and fix any potential issues before they become major problems.

Oil your machine regularly to keep the moving parts lubricated and running smoothly.

Check the tension on your machine regularly to ensure it’s set correctly for the materials you’re working with.

Keep your machine covered when not in use to protect it from dust and debris.

A cobbler sewing machine consists of different parts that work together to sew leather and other tough materials. We will discuss the ten essential parts of a cobbler sewing machine that you need to know.

The base or bed is the mainframe of the cobbler sewing machine. It’s a flat surface that holds all the parts of the machine. The base is usually made of cast iron, which makes it strong and durable.

The arm is the part that holds the needle and the presser foot. The arm moves up and down as the needle goes through the leather, creating the stitch. The arm’s movement is controlled by a foot pedal, which is pressed by the operator to start and stop the machine.

The needle is the most critical part of the cobbler sewing machine. It’s a long, thin, and pointed metal rod that passes through the leather, making the stitch. The needle’s size varies depending on the type of leather and the thickness of the thread used. The needle must be sharp to pierce through the leather easily.

The presser foot is the part that holds the leather in place as the needle stitches through it. It’s a flat metal piece that presses the leather against the feed dog, ensuring that the stitch is even and uniform.

The feed dog is a set of metal teeth that move the leather forward as the needle goes up and down. The feed dog ensures that the stitch is straight and even by moving the leather at a constant speed.

The bobbin is a small spool of thread that sits inside the bobbin case under the needle plate. The thread from the bobbin feeds through a small hole, creating the bottom stitch.

The bobbin case holds the bobbin in place and ensures that the thread feeds smoothly through the machine. The bobbin case is usually made of metal and can be removed for cleaning or replacing the bobbin.

The tension discs control the amount of tension on the thread. They are located above the needle and control the thread’s flow through the machine, ensuring that the stitch is even and tight.

The thread guide directs the thread from the spool to the needle, ensuring that it doesn’t tangle or break. The thread guide is usually made of metal and is located above the tension discs.

The motor powers the cobbler sewing machine, allowing it to stitch through thick leather and tough materials. The motor is usually located at the base of the machine and can be operated by a foot pedal or a power switch.

While a regular sewing machine can be used for some shoemaking tasks, it’s not ideal for working with heavy-duty materials like leather and rubber. A cobbler sewing machine is designed specifically for these types of materials and can produce stronger, more durable stitches.

The cost of a cobbler sewing machine can vary widely depending on the type, brand, and features. You can expect to pay anywhere from a few hundred to several thousand dollars for a high-quality cobbler sewing machine.

While cobbler sewing machines are designed for professionals, with a little practice and patience, anyone can learn to use one. It’s always a good idea to start with smaller projects and work your way up to more complex designs.

If you’re serious about shoemaking or other leathercraft projects, investing in a cobbler sewing machine is a smart move. With their durability, precision, and speed, these machines can help you take your work to the next level and achieve professional-quality results. By following the tips and guidelines in this guide, you can choose the right cobbler sewing machine for your needs and keep it in top condition for years to come.

Here is the list of the 7 best cobbler sewing machines for 2024.

| Features | Cons | |

|---|---|---|

| Brand OLenyer, The leather stitching machine can use nylon or cotton threads to sew different materials, such as leather shoes, rubber shoes, sports shoes,…(Alloy Steel)

Is Electric No |

Amazon | |

| Brand FamYun, Leather Sewing Machine Dual Cotton Nylon Line Sewing Machine Manual Leather Machine Shoe Sewing Machine (Cast Iron)

Is Electric No |

Amazon | |

| Brand ColouredPeas, The New Cobbler Machine 10 -Bearings,Shoe Repair Hand Leather Sewing Machine,…(Aluminum, Iron)

Is Electric No |

Amazon | |

| Brand BACHIN, Shoe Repair Machine Hand Cobbler Sewing Machine dual Cotton Nylon Line Sewing Machine Manual Leather Machine for Shoes Cloth Bags(Iron)

Is Electric No |

Amazon | |

| Brand FAHKNS, FAHKNS Shoe Repair Machine Handheld Leather Sewing Machines Cobbler Stitching Industrial Heavy Duty Maquina de Coser Manual Nylon Line for Upsolery Zippers Coats Bags Clothes Quilts Trousers Belt(Aluminum)

Is Electric No |

Amazon | |

| Brand GCCSJ, Leather Sewing Machine Cobbler Stitching Machine Shoe Repair Machine with Dual Cotton Nylon Line for Sewing Upsolery, Bags, Tents, Clothes, Belt and Coats(Aluminum)

Is Electric No |

Amazon | |

| Brand Toolly, Toolly Leather Hand Shoe Repair Machine, Upgraded Aluminum Alloy Frame – Antirust and Sturdy, Small Heavy Duty Cobbler leather Sewing Machine for Manual Sewing Dual Cotton Nylon Line(Aluminum, Iron)

Is Electric No |

Amazon |